Iron oxide granules are a versatile material, essential in multiple industries.

Iron oxide granules are used in pigments, construction, and wastewater treatment. They provide consistent color, environmental benefits, and high-performance results across diverse applications.

Discover how these small but mighty granules impact industries worldwide and why they continue to grow in demand.

What are iron oxide granules?

Iron oxide granules are a processed form of iron oxide, commonly used for industrial applications. But why are they significant?

They are compacted particles of iron oxide, designed for easy handling, uniformity, and improved performance in various applications.

Iron oxide granules are produced through a granulation process, ensuring consistency in size and density. These characteristics make them more efficient and easier to manage compared to powder forms. Available in various colors, such as red, yellow, and black, these granules are widely used as pigments. Beyond aesthetics, their chemical properties allow them to act as a key component in catalytic and adsorption processes.

Granules also offer practical benefits. Their larger particle size reduces dust, improving workplace safety and reducing material loss. They are also more stable during storage, with less risk of caking or degradation, making them a preferred choice for industries needing precision and reliability.

What are the applications of iron oxide granules?

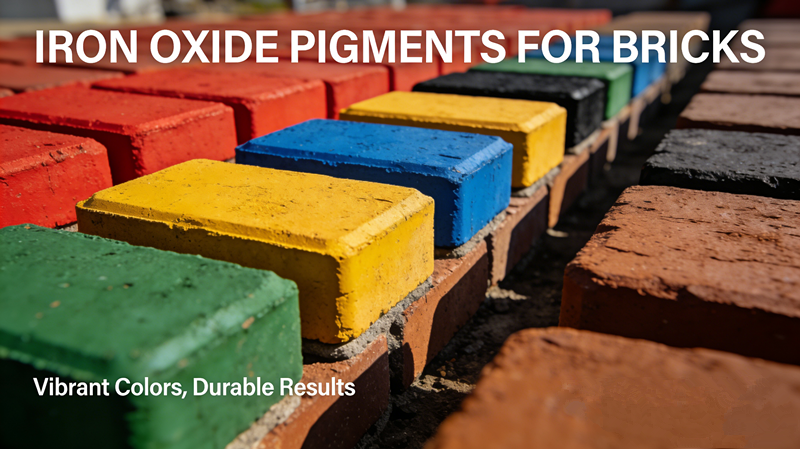

From coloring bricks to purifying air, iron oxide granules play crucial roles in various fields. How exactly are they used?

Iron oxide granules are used in pigments, construction materials, ceramics, water purification, and catalysis, offering versatility and high functionality.

Applications in Different Industries:

| Industry | Use | Benefits |

|---|---|---|

| Construction | Coloring concrete, bricks, and pavers | Long-lasting, consistent colors |

| Water Treatment | Adsorption of contaminants | Effective removal of impurities |

| Paints and Coatings | Base for durable pigments | UV resistance and color retention |

| Ceramics | Coloring for tiles and ceramics | High-temperature stability |

| Chemical Catalysis | Catalyst support in reactions | Improved reaction efficiency |

In construction, granules are widely used to color building materials, providing durability and vibrant finishes. In water treatment, they act as adsorbents for removing heavy metals and impurities. Their high stability makes them perfect for paints and coatings, ensuring lasting color. The versatility of iron oxide granules is unmatched, allowing industries to achieve precision and efficiency.

Advantages of Using Iron Oxide Granules

Why do industries prefer iron oxide granules over alternatives? What makes them a go-to material?

Iron oxide granules provide benefits like low dust, easy handling, consistent performance, and environmental safety, making them superior to powders.

Key Advantages:

-

Reduced Dust and Improved Safety

Granules generate less airborne dust compared to powders, ensuring a safer working environment. This reduces health risks for workers and minimizes product loss. -

Ease of Handling

The compact form of granules allows for easier transport, storage, and mixing, saving time and reducing logistical challenges. -

Uniform Performance

Granules are processed for uniform size and density, providing consistent results in applications. This is critical for industries like construction and paints. -

Environmentally Friendly

Iron oxide granules are often produced sustainably and are non-toxic, aligning with global trends toward eco-friendly solutions.

Trends in the Global Market

How is the demand for iron oxide granules evolving worldwide? What drives their growth?

The global market for iron oxide granules is growing due to demand from construction, environmental, and industrial sectors. Emerging markets are key growth drivers.

Market Trends and Insights:

-

Rising Construction Activities

Developing countries are investing in infrastructure, driving demand for high-quality pigments and materials. Iron oxide granules are at the forefront of this demand. -

Sustainability Focus

Industries are prioritizing eco-friendly materials. Iron oxide granules, with their non-toxic nature, fit perfectly into this trend. -

Technological Advancements

Innovations in production processes have improved the quality and cost-effectiveness of granules, making them more accessible. -

Regional Growth Patterns

Regions like Asia-Pacific, Africa, and South America are experiencing rapid urbanization, leading to increased consumption of iron oxide granules for construction and water treatment.

Conclusion

Iron oxide granules are indispensable across industries, offering unmatched versatility and reliability. Their applications range from construction to environmental solutions, underpinned by unique advantages like uniformity, safety, and sustainability. As global trends favor eco-friendly and efficient materials, the demand for iron oxide granules continues to rise, solidifying their role in modern industry.