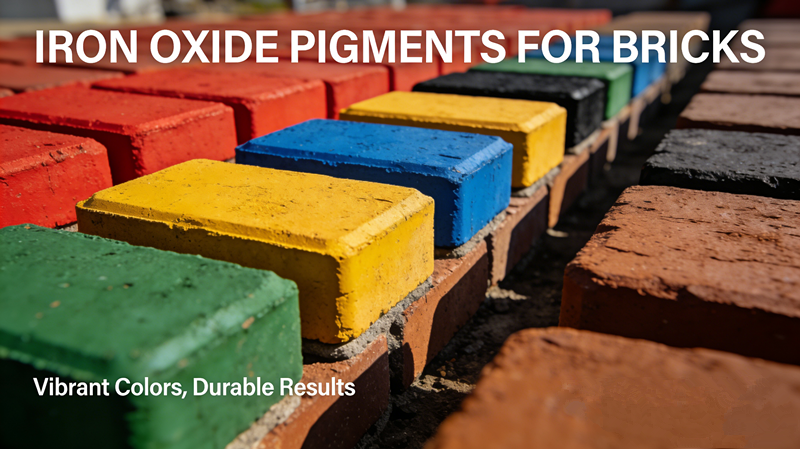

Iron oxide pigments are among the most widely used inorganic pigments in the world. Their popularity spans across industries such as construction, coatings, plastics, ceramics, and more—thanks to their excellent durability, non-toxicity, and wide range of colors. Among the available shades, red, yellow, black, brown, and orange iron oxide pigments are the most common. But how do these different colors compare in performance?

This article explores the technical characteristics, strengths, and limitations of each major pigment color, offering a side-by-side comparison based on key performance factors such as color stability, dispersibility, chemical resistance, and heat tolerance.

Red Iron Oxide: The Leader in Stability

Red iron oxide (Fe₂O₃) is the most popular and widely produced pigment. It is well-known for its outstanding UV and weather resistance, making it the top choice for outdoor applications like concrete bricks, paving stones, and roofing tiles.

Performance highlights:

- Color Strength: High

- Lightfastness: Excellent

- Chemical Resistance: Good

- Heat Stability: Up to 800°C

Opinion: Red iron oxide sets the standard. Its deep, earthy tone is not only stable under sunlight but also resists alkalis in cement very well. For brick and concrete manufacturers, it’s the most reliable pigment for long-term projects.

Yellow Iron Oxide: Sensitive but Versatile

Yellow iron oxide offers bright, warm tones that are attractive for coatings and plastics. However, it is more sensitive to heat compared to red or black pigments.

Performance highlights:

- Color Strength: Medium

- Lightfastness: Good

- Chemical Resistance: Moderate

- Heat Stability: Up to 180°C (beyond this, it converts to red)

Opinion: Yellow iron oxide is great for applications where low temperature and vibrant color matter. But in high-heat applications, it's not ideal. In fact, some manufacturers deliberately calcine yellow pigment to produce red pigment, which speaks volumes about its thermal limitations.

Black Iron Oxide: Powerful but Heavy

Black iron oxide (Fe₃O₄) is prized for its strong tinting strength and is often used in cement, ceramics, and magnetic materials.

Performance highlights:

- Color Strength: Very High

- Lightfastness: Excellent

- Chemical Resistance: High

- Heat Stability: Up to 300°C

Opinion: The deep, rich black of Fe₃O₄ makes it the best choice for strong base coloring. However, it tends to be heavier and harder to disperse in some liquid systems. I think it's ideal for bricks and mortar but needs more work in plastics or paints unless surface-treated.

Brown Iron Oxide: A Functional Middle Ground

Brown pigments are generally blends or naturally occurring oxides. They offer balanced coloring, often used when a muted or earthy tone is desired.

Performance highlights:

- Color Strength: Moderate

- Lightfastness: Good

- Chemical Resistance: Good

- Heat Stability: Up to 500°C

Opinion: Brown oxide pigments are reliable but don’t offer standout features. Their biggest strength is consistency. In architectural applications or landscaping bricks, they offer a more natural aesthetic, which is increasingly popular.

Orange Iron Oxide: Limited but Eye-Catching

Orange iron oxide is less commonly used, usually derived from yellow or red bases. It offers bright, warm tones, often used in specialty coatings or plastics.

Performance highlights:

- Color Strength: Medium

- Lightfastness: Good

- Chemical Resistance: Moderate

- Heat Stability: Moderate

Opinion: Orange is more of a niche pigment. It adds vibrancy in the right settings but is limited by availability and cost. It doesn’t compete with red or black in terms of durability or tinting strength.

Final Thoughts

Each color of iron oxide pigment comes with unique advantages. Red and black are the top performers in terms of stability and strength. Yellow is excellent for bright tones but must be protected from high heat. Brown provides a safe middle ground, while orange is suitable for special applications.

From a technical and practical perspective, red iron oxide remains the most versatile and high-performing pigment, especially in building materials. For projects requiring darker tones, black offers unmatched coverage. Yellow and orange are great for aesthetics but need more careful handling.

When selecting a pigment, it's essential to weigh performance factors against your application needs. The right choice can enhance product quality, durability, and cost-efficiency.