A Practical Buyer’s Guide Based on Real Procurement Scenarios

Iron oxide pigments are often described as “stable” and “easy to use,” yet experienced buyers know that pigment selection can directly affect product consistency, customer complaints, and long-term supply reliability. Many purchasing issues do not appear during initial sampling but emerge after months of production.

This article addresses the questions buyers repeatedly raise during procurement discussions, audits, and post-delivery evaluations, with a focus on how decisions made at the pigment level influence downstream production results.

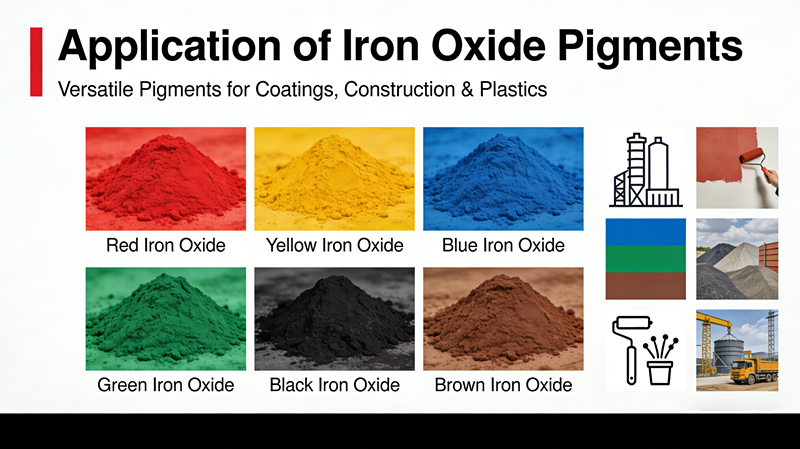

Are All Iron Oxide Pigments Technically Interchangeable?

This is one of the most underestimated questions in pigment purchasing.

Although iron oxide pigments share similar chemical names, they are not interchangeable in practical use. Differences in particle morphology, surface treatment, and calcination control lead to measurable variation in:

- Tinting strength

- Dispersion behavior

- Color undertone

- Heat stability during curing or firing

For example, two iron oxide red pigments with the same CAS number may produce noticeably different shades once mixed with cement due to particle size distribution. This becomes critical in applications where batch-to-batch color uniformity is required, such as paving blocks or prefabricated concrete panels.

Buyers who switch suppliers without validating these parameters often face color deviation complaints even when lab data appears similar.

Why Do Pigments Perform Well in the Lab but Fail in Mass Production?

This question usually comes from buyers after scale-up problems occur.

Laboratory testing typically uses:

- Small batch mixing

- Controlled dispersion time

- Ideal temperature and humidity

However, industrial production introduces:

- Faster mixing cycles

- Uneven moisture content

- Variable curing conditions

Iron oxide pigments with weaker dispersion characteristics may pass lab tests but show color streaking, spotting, or uneven distribution during full-scale manufacturing. This is especially common in dry-mix systems or automated batching lines.

Experienced buyers increasingly request production-line testing, not just lab reports, before approving new pigment suppliers.

How Does Particle Size Affect Color Stability Over Time?

Particle size is not only related to color strength; it also influences long-term color retention.

- Finer particles offer stronger tinting strength but may agglomerate if dispersion is insufficient.

- Coarser particles disperse more easily but may produce weaker color depth.

In outdoor applications, poorly controlled particle size can lead to:

- Surface chalking

- Uneven fading

- Visual color drift between batches produced months apart

Buyers producing exterior construction materials often prioritize controlled particle size distribution rather than maximum color strength.

Why Does the Same Dosage Produce Different Results in Different Cement Systems?

This is a common concern in international trade.

Cement properties vary by region due to:

- Raw material composition

- Alkali content

- Fineness and whiteness

A pigment dosage that works in one cement system may appear darker or duller in another. This is why dosage recommendations provided without understanding the local cement type can be misleading.

Professional buyers evaluate pigments based on color efficiency relative to their own cement, not absolute dosage percentages.

What Causes Batch-to-Batch Color Variation?

Batch inconsistency is one of the most expensive problems in pigment supply chains.

Common causes include:

- Inconsistent raw material sourcing

- Variations in calcination temperature

- Insufficient quality control during milling

Even minor deviations can accumulate over time, leading to visible shade differences in finished products. This is particularly risky for buyers supplying large infrastructure or long-term construction projects.

Reliable suppliers maintain:

- Strict process control

- Reference standard retention

- Internal shade comparison systems

Buyers often request retained samples from previous batches to verify long-term consistency.

Is Higher Tinting Strength Always Better?

Not necessarily.

High tinting strength reduces pigment dosage, but it can also:

- Increase sensitivity to dosing errors

- Make color adjustment more difficult

- Amplify dispersion problems

In automated production systems, extremely strong pigments may lead to greater color fluctuation if dosing precision is not optimal.

Many experienced buyers choose pigments with balanced tinting strength, prioritizing production stability over theoretical cost savings.

How Do Environmental and Regulatory Factors Affect Pigment Selection?

Environmental compliance increasingly affects pigment availability and pricing.

Buyers are paying closer attention to:

- Heavy metal limits

- Waste treatment standards

- Documentation completeness

Pigments that meet current regulations are more likely to ensure long-term supply continuity, especially for export-oriented manufacturers.

What Role Does Technical Support Play After Delivery?

Pigment selection does not end at shipment.

Post-delivery issues often involve:

- Color adjustment requests

- Application troubleshooting

- Process optimization

Suppliers with application experience can help buyers:

- Reduce pigment usage

- Improve dispersion efficiency

- Stabilize color across seasons

For many buyers, technical response speed becomes more important than price after the first order.

Why Do Experienced Buyers Avoid Frequent Supplier Changes?

Switching pigment suppliers introduces hidden risks:

- Requalification costs

- Color re-approval cycles

- Production disruption

Even small shade differences can require customer re-approval, especially in regulated construction projects. As a result, experienced buyers focus on long-term supplier stability, not short-term price advantages.

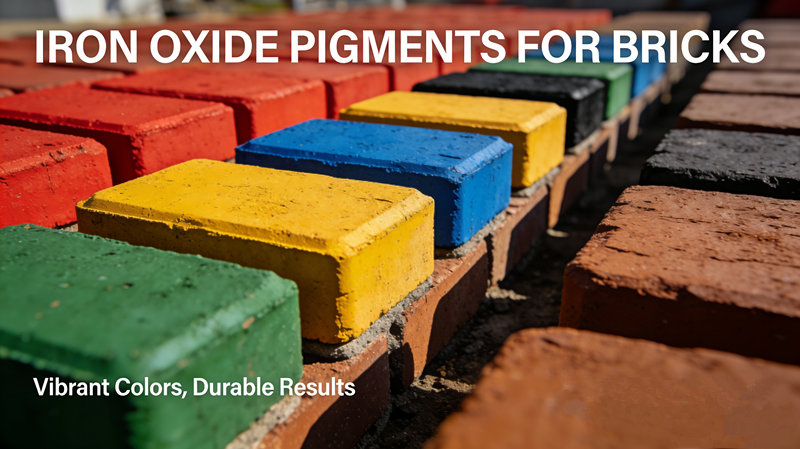

What Defines a “Suitable” Iron Oxide Pigment for Industrial Buyers?

From a buyer’s perspective, suitability is not defined by one parameter, but by a combination of:

- Consistent shade

- Stable dispersion behavior

- Predictable performance in real production

- Reliable documentation

- Long-term supply capability

Pigments that perform consistently over time reduce operational risk and support scalable production.

Conclusion

When you buy iron oxide pigment, it is not just about looking at the price. The kind of iron oxide pigment you choose affects how well your production line works, how consistent your products are, and how happy your customers are.

Buyers who evaluate pigments based on real application behavior, rather than isolated lab data, are better positioned to achieve stable, long-term results. Depth of understanding at the procurement stage often determines success months or years later.