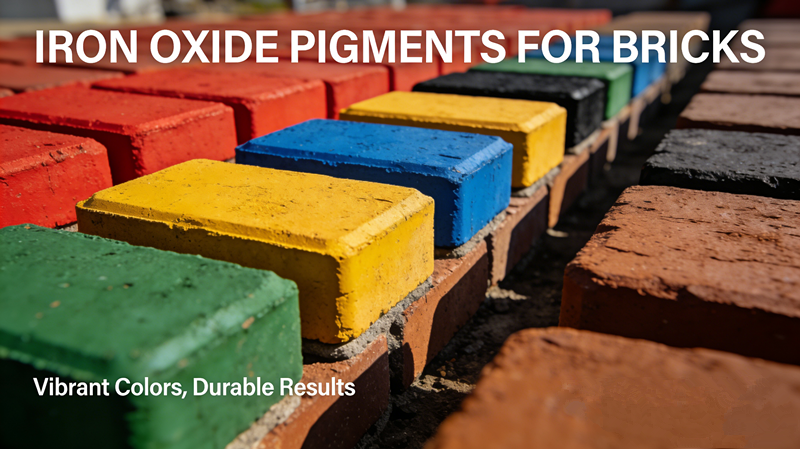

Iron oxide pigments are everywhere in our daily lives, yet few people understand their significance. These pigments provide vibrant and durable colors for construction, coatings, and plastics.

Iron oxide pigments are synthetic or natural compounds used for their excellent coloring properties, durability, and resistance to UV radiation. They are widely applied in industries such as construction, paint, and ceramics.

Understanding how to use and choose the right iron oxide pigments1 is crucial for ensuring product quality and cost efficiency.

What is Iron Oxide Pigment?

Iron oxide pigments are a type of inorganic pigment known for their strong tinting strength and excellent stability. They come in various shades, primarily red, yellow, black, and brown.

Iron oxide pigments are derived from iron and oxygen compounds, offering high opacity, chemical resistance, and weather stability. They are widely used in industries requiring long-lasting color retention.

Types of Iron Oxide Pigments

Iron oxide pigments are available in different colors, each with unique properties:

| Pigment Type | Color | Common Applications |

|---|---|---|

| Iron Oxide Red2 | Red | Bricks, paints, coatings |

| Iron Oxide Yellow3 | Yellow | Concrete, plastics, ceramics |

| Iron Oxide Black4 | Black | Asphalt, rubber, ink |

| Iron Oxide Brown | Brown | Construction, decorative materials |

These pigments can be natural or synthetic. Natural iron oxides come from mineral sources, while synthetic versions are manufactured for better consistency and purity.

What can iron oxide pigments be used for?

Iron oxide pigments are versatile, making them an essential component in various industries.

They are used in construction materials, paints, coatings, plastics, ceramics, and even cosmetics due to their excellent color stability and durability.

Major Applications

-

Construction Industry

Iron oxide pigments are commonly used in colored concrete5, paving stones, and bricks. They improve aesthetics while maintaining durability. -

Paints and Coatings

These pigments provide rich, long-lasting colors in industrial and decorative paints. Their resistance to weathering makes them ideal for outdoor applications. -

Plastics and Rubber

Iron oxides add color to plastic products while ensuring UV resistance and durability. -

Ceramics and Tiles

The high-temperature stability of iron oxides makes them perfect for coloring ceramic glazes and tiles. -

Cosmetics and Pharmaceuticals

Due to their non-toxic nature, iron oxide pigments are used in foundations, lipsticks, and pharmaceutical coatings.

How to use iron oxide pigments?

Knowing the correct way to use iron oxide pigments ensures the best results in color consistency and performance.

Iron oxide pigments should be thoroughly dispersed into the base material, whether it's concrete, paint, or plastic. Proper mixing and dosage control prevent uneven color distribution.

Best Practices for Using Iron Oxide Pigments

1. In Concrete and Mortar

- Use 3-5% pigment by weight of cement for optimal color.

- Mix dry pigment with cement before adding water to ensure even distribution.

- Avoid excessive water to prevent uneven color.

2. In Paints and Coatings

- Pre-dispersing pigments in a liquid medium improves uniformity.

- Use a high-speed mixer for better integration.

- Choose the correct pigment grade for different finishes.

3. In Plastics and Rubber

- Use masterbatch or direct mixing methods.

- Ensure uniform dispersion to prevent streaking.

- Select UV-stabilized pigments for outdoor applications.

How to choose a reliable iron oxide pigment manufacturer?

Selecting a high-quality supplier is crucial for maintaining consistency and performance in your applications.

A reliable iron oxide pigment manufacturer should offer consistent quality, certifications, customizable packaging, and timely delivery to meet industrial demands.

Key Factors in Choosing a Manufacturer

| Factor | Why It Matters |

|---|---|

| Quality Control | Ensures uniformity and purity of pigments. |

| Certifications | Compliance with industry standards like ISO, SGS. |

| Customization | Ability to provide tailored packaging and color consistency. |

| Logistics | Reliable and fast delivery with proper documentation. |

| Customer Support | Good communication and after-sales service. |

Researching a manufacturer’s reputation and visiting their production facility can help verify their reliability. Checking previous customer reviews and testing samples before bulk purchasing are also essential steps.

Choosing the right iron oxide pigment manufacturer can significantly impact your business success. XT Pigment offers a trusted, high-quality solution to meet your industrial needs.

Conclusion

Iron oxide pigments are essential in multiple industries due to their durability, versatility, and vibrant colors. Understanding their types, applications, and usage methods ensures the best results. When selecting a supplier, focusing on quality, certifications, and reliable logistics is key to long-term success. By making informed decisions, businesses can achieve cost efficiency and superior product performance.

-

Explore this link to understand the diverse applications and benefits of iron oxide pigments in industries like construction and coatings. ↩

-

Explore the diverse uses of Iron Oxide Red in various industries, enhancing your understanding of its significance. ↩

-

Discover how Iron Oxide Yellow contributes to durability and aesthetics in construction materials. ↩

-

Learn about the various industries that rely on Iron Oxide Black for its unique properties and applications. ↩

-

Learn about the process and benefits of colored concrete, which can enhance the aesthetic appeal and durability of construction projects. ↩