Iron oxide pigments have been used for centuries, yet their relevance in modern industry continues to grow. Known for their vibrant hues, stability, and versatility, these pigments are not only valued for color but also for performance across construction, coatings, plastics, ceramics, and many other applications. In today’s market, demand for iron oxide pigments1 is on the rise, driven by both aesthetic and functional requirements.

A Palette of Lasting Colors

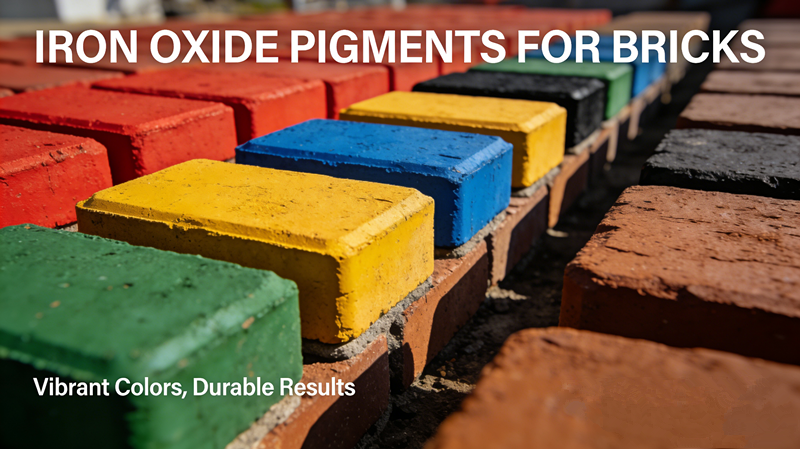

One of the most well-known qualities of iron oxide pigments2 is their strong and stable coloring ability. Available in shades of red, yellow, black, brown, and even blended tones, they provide manufacturers with a reliable range of options. Unlike organic pigments, iron oxides do not easily fade when exposed to sunlight, weather, or chemicals. This makes them a preferred choice for outdoor applications such as concrete, paving blocks, roofing tiles, and paints, where long-term durability matters.

In construction, for example, red and yellow iron oxides are widely used to give bricks and concrete blocks consistent and lasting color. Their resistance to ultraviolet degradation ensures that buildings and infrastructure maintain their appearance over decades, reducing the need for costly maintenance or repainting.

More Than Just Coloring Agents

The demand for iron oxide pigments is not only about their shades. Industries increasingly recognize the functional benefits these pigments bring. Beyond aesthetics, they contribute to performance in several ways:

- Weather Resistance3: Iron oxide pigments remain stable under harsh environmental conditions. Whether exposed to high humidity, direct sunlight, or fluctuating temperatures, their properties stay intact.

- Chemical Stability4: They are inert to many chemicals, ensuring that coatings, plastics, and construction materials remain durable in aggressive environments.

- UV Protection: Iron oxides naturally absorb ultraviolet radiation, offering protective qualities in paints, coatings, and polymers.

- Safety and Non-Toxicity: As inorganic pigments, they are considered safe for use in a wide range of applications, including food-contact materials and cosmetics.

This combination of visual and functional benefits sets iron oxide pigments apart from many alternatives.

Driving Forces Behind Rising Demand

Several global trends are fueling the increasing use of iron oxide pigments5:

-

Urbanization and Infrastructure Growth

The rapid development of cities, especially in Asia, the Middle East, and Africa, is driving demand for construction materials. Colored concrete, tiles, and paving stones are widely used in modern architecture, and iron oxides are central to achieving the desired designs. -

Sustainability and Longevity

Builders and manufacturers are under pressure to adopt sustainable solutions. Because iron oxide pigments5 are long-lasting and reduce the need for frequent replacements, they align well with green building standards and eco-conscious production. -

Expanding Use in Coatings and Plastics

From industrial coatings to automotive finishes, iron oxide pigments5 provide both appearance and protection. In plastics, they offer durable coloring that withstands heat and weather, ensuring longevity in outdoor applications. -

Cost-Effectiveness

Compared to many specialty pigments, iron oxides provide a balance of performance and affordability. This makes them a practical choice for industries that require both large-scale production and consistent quality.

Applications Across Industries

The versatility of iron oxide pigments is reflected in their widespread applications:

- Construction: Bricks, concrete blocks, roof tiles, and paving stones.

- Paints and Coatings: Exterior paints, industrial coatings, primers, and finishes.

- Plastics: Outdoor furniture, pipes, and building components.

- Ceramics and Glass: Coloring for tiles, glazes, and specialty products.

- Cosmetics and Pharmaceuticals: Non-toxic colorants for powders and tablets.

Each of these sectors relies on the pigments’ stability, durability, and cost-performance ratio.

The Future of Iron Oxide Pigments

Looking ahead, the global demand for iron oxide pigments is set to expand further. Urban growth, infrastructure investment, and increasing environmental regulations will continue to position them as an essential material. At the same time, manufacturers are working on innovations such as micronized grades for smoother dispersibility and higher-purity options for specialized applications.

As industries move toward more sustainable and long-lasting solutions, iron oxide pigments are likely to remain at the forefront. Their ability to deliver both color and performance ensures that they are not just a pigment of choice, but a material of necessity for the future.

-

Explore this link to understand the diverse applications and benefits of iron oxide pigments in various industries. ↩

-

Explore this link to understand how iron oxide pigments enhance durability and color stability in construction materials. ↩

-

Explore how Weather Resistance enhances the durability and performance of iron oxide pigments in various applications. ↩

-

Learn about the significance of Chemical Stability in ensuring the longevity and effectiveness of materials using iron oxide pigments. ↩

-

Explore this link to understand how iron oxide pigments enhance construction materials and their sustainability benefits. ↩ ↩ ↩