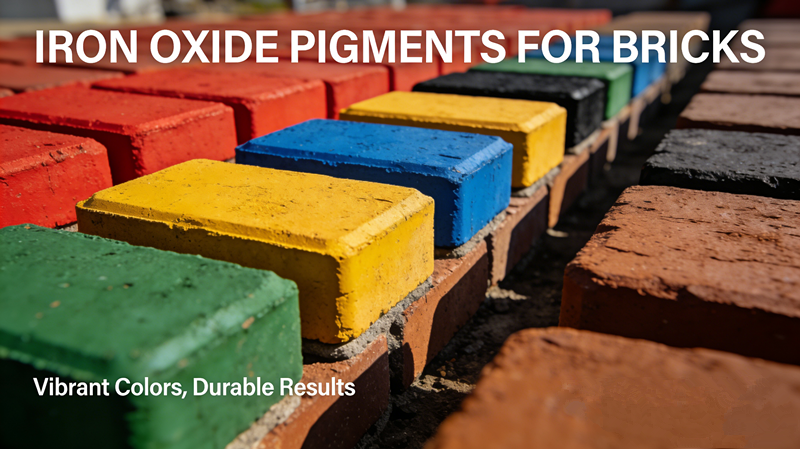

In recent years, the global construction industry has undergone a major shift toward higher aesthetic standards, improved durability, and more sustainable material choices. As a result, the demand for colored building materials1 has grown rapidly—particularly in infrastructure projects such as municipal paving, highways, landscape concrete, and modern urban redevelopment. Among all inorganic pigments, iron oxide black2 has shown the most significant growth, becoming a widely adopted color additive for concrete, asphalt, paving blocks, and precast building components.

This increase is not a coincidence. Engineers, architects, and construction material manufacturers have begun paying more attention to the visual impact of building materials. Deep black tones are considered clean, modern, and compatible with contemporary design styles. Combined with the pigment’s natural stability and compatibility with mineral-based materials, iron oxide black2 is now one of the essential pigments for production in the building materials sector.

This article explores the reasons behind this rising trend, the advantages of iron oxide black in construction applications, and what this development means for manufacturers and project teams worldwide.

Growing Demand in Concrete Applications

Colored concrete has become a standard material for modern urban spaces. From sidewalks and parking lots to decorative precast elements, the market has clearly shifted from traditional grey concrete to more expressive and visually refined alternatives. Iron oxide black3 is especially favored for the following reasons:

1. Deep, Uniform, and Long-Lasting Color

Iron oxide black3 produces a rich, dense black shade that blends naturally with cement-based materials. Unlike organic pigments, which may fade or degrade under alkaline conditions, iron oxide black remains stable even in highly alkaline concrete environments.

Its color retention under sunlight, rain, and fluctuating temperatures makes it a reliable choice for long-term outdoor applications.

2. Strong Tinting Strength and Lower Usage Costs

A key reason for its popularity is its high tinting strength, which allows manufacturers to achieve deep color using lower pigment dosages. For large concrete production facilities, such as block factories or precast plants, this translates into:

- reduced pigment consumption

- stable color performance

- lower production cost per unit

This combination of performance and affordability enables manufacturers to keep up with fast-growing demand without sacrificing product quality.

3. Excellent Dispersion in Cement Systems

For concrete producers, consistent appearance is critical. Iron oxide black4 is designed for smooth and easy dispersion, helping reduce common issues such as:

- color streaks

- uneven distribution

- surface discoloration

- batch-to-batch inconsistency

By achieving a uniform mix more quickly, factories can improve operational efficiency5 and minimize material waste.

Growing Use in Asphalt and Road Engineering

Beyond concrete, iron oxide black is being adopted increasingly across the asphalt and road construction6 sector. Modern road systems require durable materials that can withstand heavy loads, UV exposure, and extreme temperature variations.

1. High UV and Heat Stability

Asphalt pavements absorb and retain heat, making them particularly challenging environments for pigments. Iron oxide black’s ability to maintain stability under high temperatures and strong sunlight ensures:

- slow color fading

- consistent appearance over time

- improved long-term road performance

This is especially important for regions with hot climates where pavement color stability is critical.

2. Improved Road Safety and Visual Clarity

Black asphalt enhanced with iron oxide black offers improved contrast with road markings, creating clearer lane boundaries and better visibility for drivers. Cities are increasingly prioritizing visual clarity in road design to support traffic safety.

3. Expanded Use in Decorative Asphalt

Modern commercial areas and recreational zones often use colored asphalt for aesthetic enhancement7. Iron oxide black allows designers to create deeper, richer tones for:

- pedestrian walkways

- park trails

- parking areas

- commercial plazas

Its natural stability ensures that the pavement retains its designed look for years.

Why the Market Is Increasingly Choosing Iron Oxide Black

Several global construction trends are supporting this upward movement in demand.

1. Modern Urban Aesthetics

Contemporary design favors minimalist and clean visual styles. Deep black surfaces—whether concrete or asphalt—create strong contrast and are increasingly featured in:

- urban landscape upgrades

- architectural facades

- municipal pavement renovations

2. Long-Term Performance Requirements

Governments and developers expect building materials to last decades. Iron oxide black’s chemical stability, non-reactive nature, and weather resistance make it ideal for long-term infrastructure projects.

3. The Rise of Precast and Modular Construction

Precast elements require pigments with stable, repeatable performance across continuous production. Iron oxide black provides consistent shade, allowing manufacturers to meet quality standards even in high-volume operations.

4. Environmental and Safety Considerations

Iron oxide pigments are known for being:

- non-toxic

- environmentally safe

- compliant with major international standards

As sustainability becomes a global priority, demand continues to increase for pigments that combine safety with long-term performance.

Why High-Quality Iron Oxide Black Matters

Not all iron oxide black pigments on the market perform in the same way. Construction materials require pigments with:

- high tinting strength

- excellent dispersion

- stable particle structure

- consistent shade between batches

- minimal impurities

Using inferior pigments may lead to color variation, production inefficiency, or long-term fading—issues that can negatively impact both factory productivity and final project results.

High-quality iron oxide black helps manufacturers ensure:

- stable production for concrete and asphalt

- uniform appearance across large-scale projects

- reduced mixing time

- lower pigment consumption

- stronger product competitiveness

For these reasons, choosing a reliable pigment supplier has become essential for companies seeking to meet modern construction standards.

Conclusion

The significant rise in the use of iron oxide black across concrete and asphalt applications shows how the construction industry is evolving toward better aesthetics, longer durability, and more efficient materials. As global infrastructure investment continues to grow, iron oxide black will play an even more important role in delivering stable, visually refined, and high-performance building materials.

Manufacturers and engineering companies aiming to enhance the quality of their concrete or asphalt products should look closely at the type of pigment they are using. High-grade iron oxide black ensures reliable performance and gives construction materials a cleaner and more modern appearance.

About XT Pigment

XT Pigment is committed to supplying high-quality iron oxide black tailored for concrete, asphalt, paving blocks, building materials, and industrial applications. With reliable color stability, strong tinting performance, and professional technical support, XT Pigment helps customers achieve:

- consistent production

- stable material performance

- long-term color durability

As the building materials industry continues to expand, XT Pigment remains dedicated to supporting global manufacturers with dependable pigments and professional service.

Visit our website for more information: www.xtpigment.com

-

Discover how colored building materials are revolutionizing design and sustainability in construction projects. ↩

-

Explore the advantages of iron oxide black, a key pigment enhancing durability and aesthetics in modern construction. ↩ ↩

-

Explore the advantages of Iron oxide black for concrete to understand its durability and color retention in various conditions. ↩ ↩

-

Explore this link to understand how Iron oxide black enhances concrete quality and consistency. ↩

-

Discover strategies to boost operational efficiency in concrete production, leading to better productivity and reduced waste. ↩

-

This resource provides insights into innovative materials and techniques shaping the future of road construction. ↩

-

Discover how colored asphalt transforms urban spaces, making them more visually appealing and functional. ↩