Outdoor products—such as coatings, construction materials, and automotive parts—are constantly exposed to sunlight. The sun’s ultraviolet (UV) radiation is particularly harsh. Over time, it can cause materials to fade, become brittle, lose strength, and eventually fail earlier than expected.

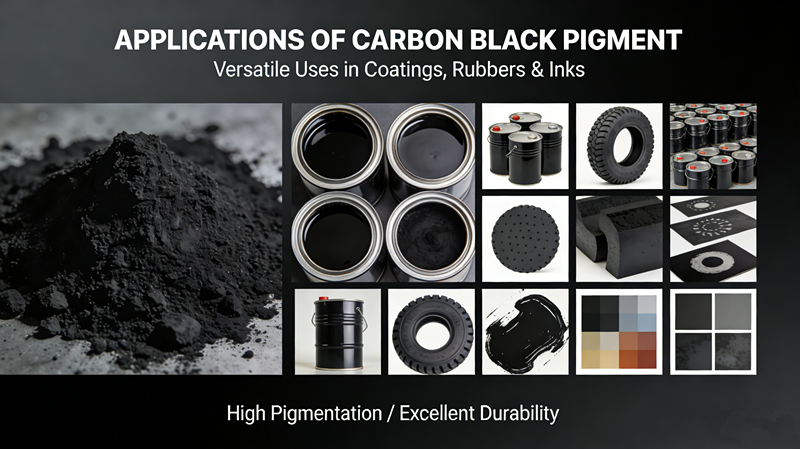

To reduce these effects, manufacturers commonly use carbon black1. Carbon black is a functional pigment that helps outdoor products resist UV damage, improving durability and extending service life. Products containing carbon black can remain outdoors for long periods without significant degradation.

In this article, we explore how carbon black1 enhances UV resistance, why it is widely used in outdoor applications, and what this means for product performance, longevity, and cost-effectiveness.

The UV Challenge for Outdoor Materials

UV radiation—especially wavelengths between 290 nm and 400 nm—has enough energy to break chemical bonds in polymers and other organic materials. This leads to several forms of degradation:

- Color fading: Unprotected plastics, coatings, and elastomers gradually lose their original appearance.

- Mechanical weakening: Materials may become brittle, crack, or lose elasticity.

- Surface deterioration: Chalkiness, surface cracks, and loss of gloss are common signs of weathering.

Without effective UV protection, outdoor products often fail long before reaching their intended service life. Preventing UV-induced degradation is therefore a key consideration in material design and formulation.

Carbon Black: A Natural UV Shield

Carbon black is a finely divided form of elemental carbon, produced through controlled combustion processes. It is one of the most widely used pigments and performance additives in plastics, coatings, and rubber.

While carbon black2 is well known for providing deep black or dark coloration, its UV-protective properties3 are equally important—especially for outdoor applications.

1. UV Absorption and Energy Conversion

Carbon black is highly effective at absorbing UV radiation4. Compared with many other materials, it can capture a broad range of harmful UV wavelengths.

When UV rays strike carbon black particles, the energy is absorbed and converted into low-level heat. This heat is far less damaging than direct UV radiation. As a result, the underlying material is protected from photochemical damage.

This absorption process significantly reduces the amount of UV energy that reaches and damages the base material. By converting harmful UV to benign heat, carbon black acts like a microscopic sunscreen within the material itself.

2. UV Scattering and Physical Shielding

In addition to absorption, carbon black also scatters UV light. Its extremely small particle size and high surface area cause incoming UV radiation to be deflected rather than penetrating deeply into the material.

When carbon black is well dispersed throughout a polymer or coating, it forms a physical barrier that limits UV penetration. This shielding effect is especially valuable in thin outdoor components, where UV damage is concentrated near the surface.

Performance Benefits Beyond UV Resistance

The main thing people think about when they hear about carbon black is that it protects us from the suns rays. But carbon black5 does a lot more than just provide UV protection6. It also gives products some other really useful benefits that make them work better when you use them outside.

Reinforcement and Mechanical Integrity

Carbon black acts as a reinforcing filler in polymers and rubber compounds. It can improve:

- Tensile strength

- Impact resistance

- Stiffness

- Abrasion resistance

These properties are critical for outdoor products exposed to mechanical stress and environmental wear.

Aesthetic Durability

Outdoor products must not only perform well but also maintain their appearance. Sun exposure often causes fading and surface degradation in plastics and coatings.

Carbon black provides a stable, uniform color that resists fading over time. Products containing carbon black7 maintain a consistent appearance even after prolonged exposure to sunlight, improving both durability and user satisfaction.

How Carbon Black Is Used Across Outdoor Applications

The UV resistance benefits of carbon black depend on proper formulation and grade selection. Common outdoor applications include:

Plastics and Polymers

In outdoor plastics—such as pipes, geomembranes, agricultural films, and molded parts—carbon black is blended directly into the polymer. It protects against UV-induced chain scission and embrittlement while maintaining mechanical performance.

Finer carbon black grades with higher surface area provide stronger UV protection and often require lower loading levels.

Industrial Coatings

Outdoor coatings are vulnerable to chalking, fading, and loss of adhesion due to UV exposure. Carbon black pigments absorb and scatter UV radiation, slowing the photo-oxidative degradation of binders and pigments.

This makes carbon black suitable for architectural, industrial, and automotive coatings designed for long-term outdoor use.

Rubber and Elastomers

Rubber products such as outdoor hoses, seals, and tires are constantly exposed to sunlight and weather. Carbon black shields the rubber matrix from UV radiation, reducing surface cracking and significantly extending service life.

Choosing the Right Carbon Black for UV Resistance

UV protection performance depends on several technical factors:

- Particle size: Smaller particles provide higher surface area and stronger UV absorption.

- Surface area: High surface area grades enhance protection at lower dosages.

- Dispersion quality: Uniform dispersion ensures consistent UV protection and avoids weak points.

Manufacturers typically balance UV resistance with color strength, mechanical reinforcement, and processing requirements to achieve optimal performance for specific outdoor applications.

Conclusion: Sustainable UV Protection With Carbon Black

In outdoor products, UV resistance is not optional—it’s essential for product longevity, reliability, and customer satisfaction. Carbon black plays a crucial role by transforming harmful UV radiation into harmless heat, shielding materials at the particle level, and reinforcing structural performance. Whether used in plastics, coatings, or rubber compounds, carbon black extends service life, preserves aesthetics, and enhances overall product quality.

For industrial manufacturers seeking durable, cost-effective solutions for outdoor applications, understanding and leveraging carbon black’s UV protective properties is a competitive advantage that supports both long-term performance and market appeal.

-

Discover how carbon black improves UV resistance in outdoor products, ensuring durability and longevity. ↩ ↩

-

Exploring carbon black's applications can provide insights into its significance in manufacturing and product development. ↩

-

Understanding UV-protective properties can enhance your knowledge of material durability and outdoor application effectiveness. ↩

-

Explore how carbon black's UV absorption can enhance material longevity and safety. ↩

-

Exploring this link will reveal the diverse applications and advantages of carbon black beyond UV protection. ↩

-

This resource will help you understand the science behind UV protection and its importance in outdoor products. ↩

-

Explore this link to understand how carbon black enhances the longevity and appearance of outdoor products, ensuring they look great over time. ↩