Iron oxide pigments are widely used in various industries due to their excellent color stability, non-toxicity, and cost-effectiveness. These pigments are derived from natural or synthetic iron compounds and are available in a range of vibrant colors, including red, yellow, brown, and black.

They are primarily used in applications like paints, coatings, concrete, ceramics, and bricks, making them an essential component in the manufacturing of products that require color enhancement and durability.

In this article, we will explore the different applications of iron oxide pigments, their benefits, and most importantly, how to choose high-quality pigments for your needs.

Applications of Iron Oxide Pigments

Iron oxide pigments are widely used and can be found in a variety of industries, such as:

Construction and building materials

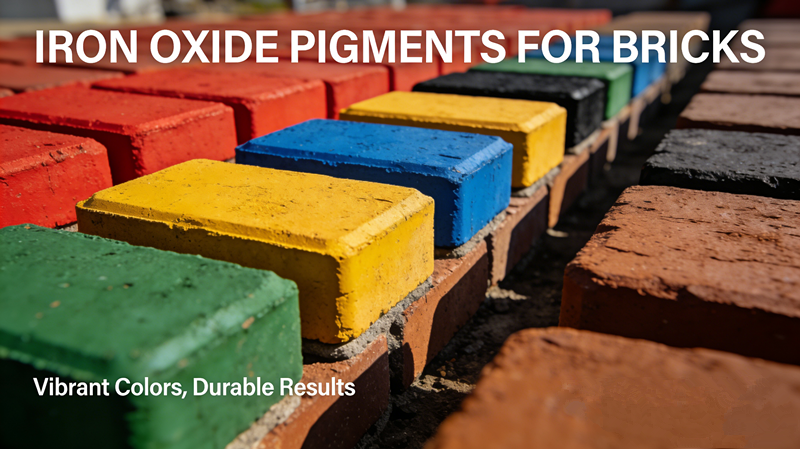

One of the most important uses of iron oxide pigments is in the production of colored concrete, cement, and bricks. Iron oxide pigments can produce a wide range of colors, making them ideal for decorative concrete, building facades, and paving tiles. They are resistant to fading and weathering, ensuring that the color is retained for a long time, making them ideal for outdoor applications.

Paints and coatings

Iron oxide pigments are often used in the production of paints, coatings, and varnishes. These pigments provide excellent covering properties and help extend the life of the coating as they are highly resistant to UV rays and environmental conditions.

Ceramics

Iron oxide pigments are often used in ceramic glazes to produce rich earthy tones and vibrant colors. Their ability to withstand high temperatures during the firing process makes them ideal for use in pottery, tiles, and other ceramic products.

Plastics and rubber

Iron oxide pigments are also used in the plastics and rubber industries to color products such as automotive parts, toys, and household items.

Cosmetics and food

Although iron oxide pigments are less common in industrial applications, they are sometimes used in cosmetics and food colorants due to their safety and non-toxic properties.

How to Choose High-Quality Iron Oxide Pigments

When choosing iron oxide pigments for any application, it is vital to consider several factors that will ensure that the pigment performs well and meets your requirements. Here are some key aspects to consider when choosing high-quality iron oxide pigments:

Color consistency and strength

The most important characteristic of iron oxide pigments is their color. High-quality pigments should provide consistent color throughout the batch and offer excellent color intensity, which directly affects the richness and vividness of the final product.

Purity and composition

Iron oxide pigments come in different compositions, including natural and synthetic varieties. Synthetic pigments generally provide more consistent and vivid colors. The purity of the pigment can also affect its performance. High-purity iron oxide pigments have fewer impurities, ensuring that they provide better color intensity, fewer contaminants, and more consistent results.

Particle size

The particle size of iron oxide pigments can affect its performance. Finer particles provide a smoother surface and better dispersion in a variety of materials. On the other hand, for applications such as concrete that require a more textured surface, a coarser pigment may be preferred. Choose a pigment with the appropriate particle size based on your specific application.

Weatherability

For outdoor applications, it is critical to choose a pigment with strong weatherability. Iron oxide pigments are naturally resistant to UV rays and moisture, but the quality of the pigment can vary. High-quality pigments will retain their color and integrity over time, even in harsh environmental conditions.

Certifications and Standards

When sourcing iron oxide pigments, make sure they meet the required industry standards and certifications. This ensures that the pigment is safe for use in a variety of applications, such as construction, coatings, and even food and cosmetics.

Conclusion

Iron oxide pigments are an essential component in many industries due to their versatility, color stability, and non-toxic properties. Whether you're involved in manufacturing paints, coatings, ceramics, or construction materials, selecting the right iron oxide pigment is crucial for ensuring product quality and performance.

By considering factors like color consistency, purity, chemical resistance, and weathering resistance, you can choose high-quality pigments that meet your specific needs. Always work with reputable suppliers who can provide products that adhere to industry standards and deliver long-lasting results.

For more infomations, stay tuned to our official website :xt pigment