Red iron oxide is a vital material in many industries. It offers strong color stability, excellent durability, and resistance to environmental factors. Its widespread applications make it an indispensable pigment in various fields.

Red iron oxide is primarily used as a pigment, but its benefits go beyond just coloring. It is valued for its chemical stability, cost-effectiveness, and compatibility with multiple materials, making it a top choice in construction, coatings, plastics, and ceramics.

Red iron oxide is not just about color—it is about performance. Understanding its properties and applications can help businesses make informed decisions when selecting materials.

What is Red Iron Oxide?

Red iron oxide is a naturally occurring mineral composed of iron and oxygen. It is known for its deep red hue and chemical stability, making it a preferred pigment in various applications.

Red iron oxide is an inorganic pigment derived from hematite. It is known for its strong tinting strength, resistance to UV degradation, and non-toxic nature, making it ideal for industrial and artistic use.

Red iron oxide's chemical stability and vibrant color make it a preferred choice in various applications. Its natural occurrence as hematite allows for easy extraction and processing, ensuring a consistent supply for industrial needs.

Production Methods

There are two primary ways to produce red iron oxide:

| Method | Description |

|---|---|

| Natural | Extracted from hematite ore and refined for purity. |

| Synthetic | Produced through chemical precipitation for consistent quality. |

Synthetic red iron oxide is preferred for industrial applications due to its uniformity and purity.

The Main Uses of Red Iron Oxide

Red iron oxide is widely used in multiple industries due to its versatility. It provides long-lasting color and enhances material performance.

The most common applications of red iron oxide include construction materials, paints, coatings, ceramics, and plastics. Its durability and UV resistance make it suitable for both indoor and outdoor use.

Key Industries Using Red Iron Oxide

-

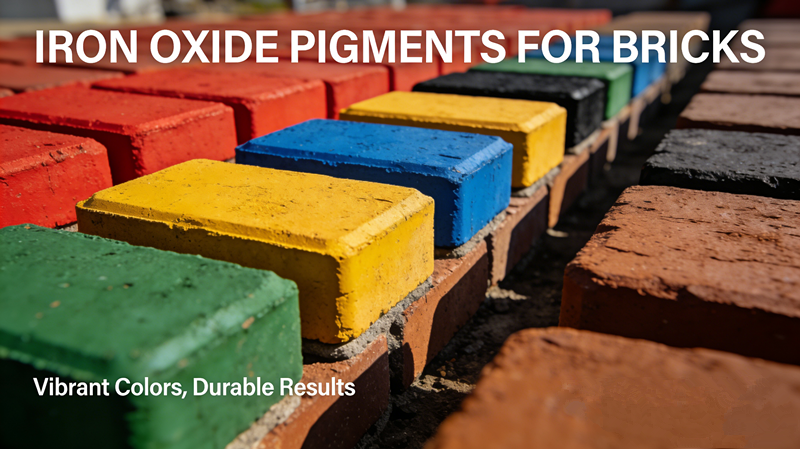

Construction Industry

- Used in concrete, bricks, tiles, and paving stones.

- Enhances aesthetic appeal and improves longevity.

-

Paints and Coatings

- Provides rich, long-lasting color.

- Resists UV rays, moisture, and chemicals.

-

Ceramics and Glass

- Used as a glaze pigment for vibrant colors.

- Withstands high temperatures without fading.

-

Plastics and Rubber

- Added to plastic materials for color stability.

- Improves weather resistance and durability.

What Can Red Iron Oxide Do in Industry?

Red iron oxide plays a crucial role in industrial applications. Its properties enhance material performance and increase durability.

Red iron oxide improves the structural integrity of materials, enhances UV and weather resistance, and ensures long-lasting coloration. It is used in high-performance coatings, concrete reinforcement, and industrial manufacturing processes.

Industrial Advantages of Red Iron Oxide

1. Strengthens Materials

- Improves the hardness and durability of concrete and bricks.

- Prevents color fading in harsh environmental conditions.

2. Chemical Resistance

- Resists acids, alkalis, and UV exposure.

- Ensures longevity in outdoor applications.

3. Eco-Friendly and Non-Toxic

- Safe for human handling and environmental use.

- Meets international safety and quality standards.

Where Can I Buy Red Iron Oxide?

If you're looking to purchase red iron oxide, several suppliers offer this compound for industrial and artistic applications.

For high-quality red iron oxide, consider XT Pigment, a leading supplier specializing in iron oxide pigments for construction, coatings, and industrial applications.

Conclusion

Red iron oxide is not just a pigment—it is a critical component in industrial development. Many buyers focus only on color, but understanding its technical advantages can lead to better purchasing decisions.

**For businesses in construction, coatings, or manufacturing, selecting high-quality red iron oxide ensures product reliability and customer satisfaction. Investing in premium pigment leads to long-term cost